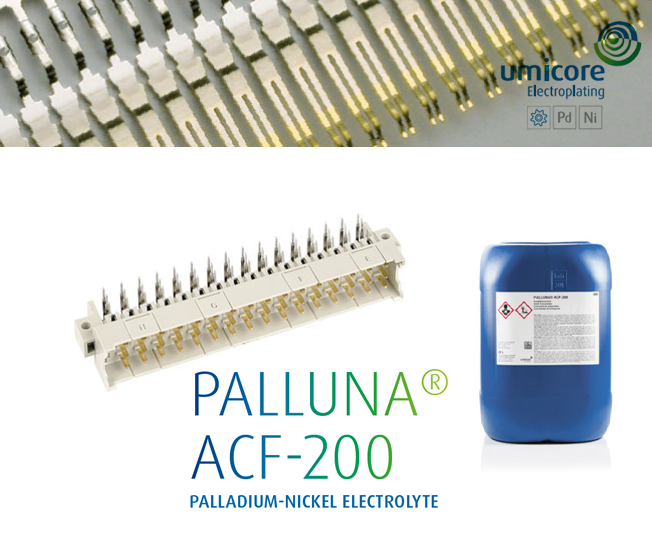

PALLUNA® ACF-200 Palladium-Nickel Electrolyte

This combination does not exist.

PALLUNA® ACF-200 Palladium-Nickel Electrolyte

PALLUNA® ACF-200 is operated without ammonia, thus avoiding offensive smells caused by pungent ammonia gases. Since no chloride is used in the electrolyte, the lifetime of the anodes is considerably longer and equipment corrosion is strongly reduced. By means of continuous active carbon purification, interfering organic decomposition products can be effectively removed from the electrolyte.

Depending on the operating conditions, the electrolyte deposits alloy coatings containing approx. 80 % of palladium. The palladium-nickel layers are hard, resistant to wear and corrosion, they are characterized by good ductility and low internal stress. In combination with flash gold, bondabilities comparable to those of soft gold surfaces can be reached.

PALLUNA® ACF-200 has the cost advantage on its side: With contact properties similar to those of hard gold, palladiumnickel is the clearly less expensive alternative.

Advantages

- Palladium-nickel electrolyte free from ammonium and chloride for printed circuit board applications

- No offensive smell caused by ammonia gas

- Longer lifetime of anodes

- Reduced equipment corrosion

- Ductile and crack-free coatings

- Excellent abrasion resistance

- Constant alloy composition of the coatings

- Solder- and bondability, especially with goldflash

Applications

- Printed circuit boards

- Contacts on plug-in cards

- Smartcards

Umicore is a global materials technology and recycling group, with about 10,000 employees and a turnover of € 10.4 billion in 2015. Umicore generates the majority of its revenues and dedicates most of its R&D efforts to clean technologies, such as emission control catalysts, materials for rechargeable batteries and recycling. Umicore’s overriding goal of sustainable value creation is based on an ambition to develop, produce and recycle materials in a way that fulfils its mission: materials for a better life.